Exploring materials that could store hydrogen safely at extreme cold temperatures.

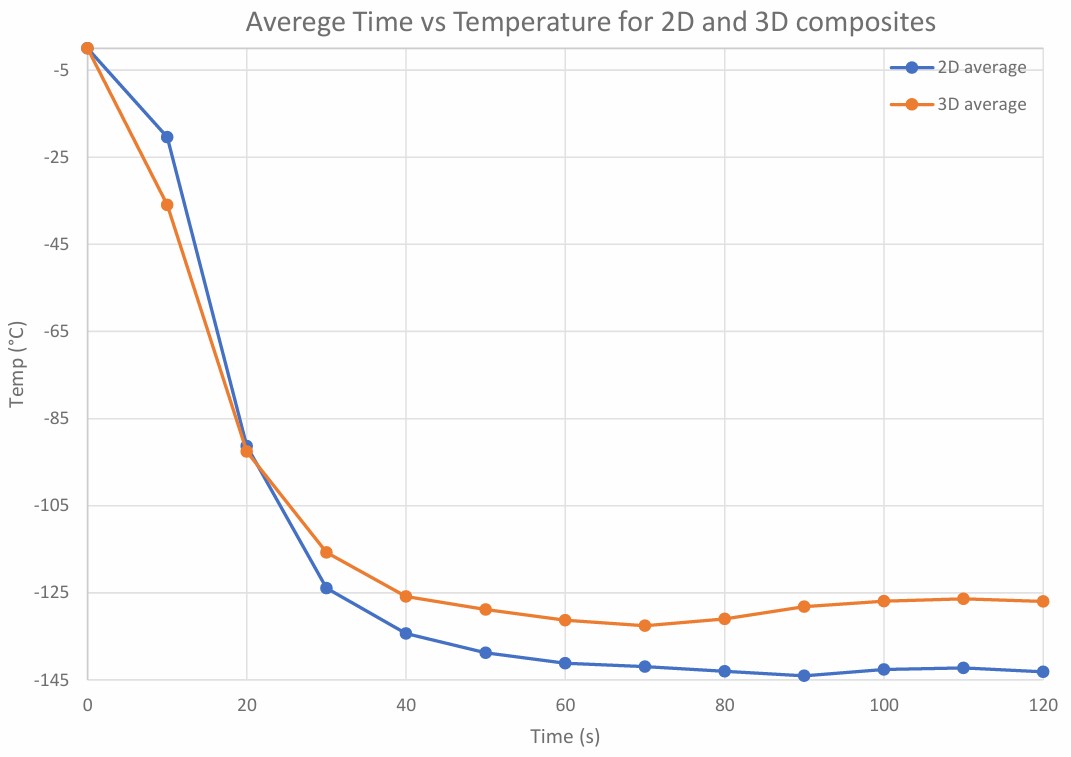

Hydrogen is one of the cleanest fuels we have — but storing it is a huge challenge. To keep hydrogen in liquid form, it must be cooled to -253°C. At these extreme temperatures, normal materials become brittle and fail. My dissertation explored whether advanced composite materials could withstand these conditions, offering safer and lighter storage tanks for hydrogen energy.

Hydrogen is more energy-dense as a liquid. If we can build tanks that are lightweight and that hold liquid hydrogen safely, we unlock a clean fuel for cars, planes, and industry — cutting reliance on fossil fuels and reducing emissions.

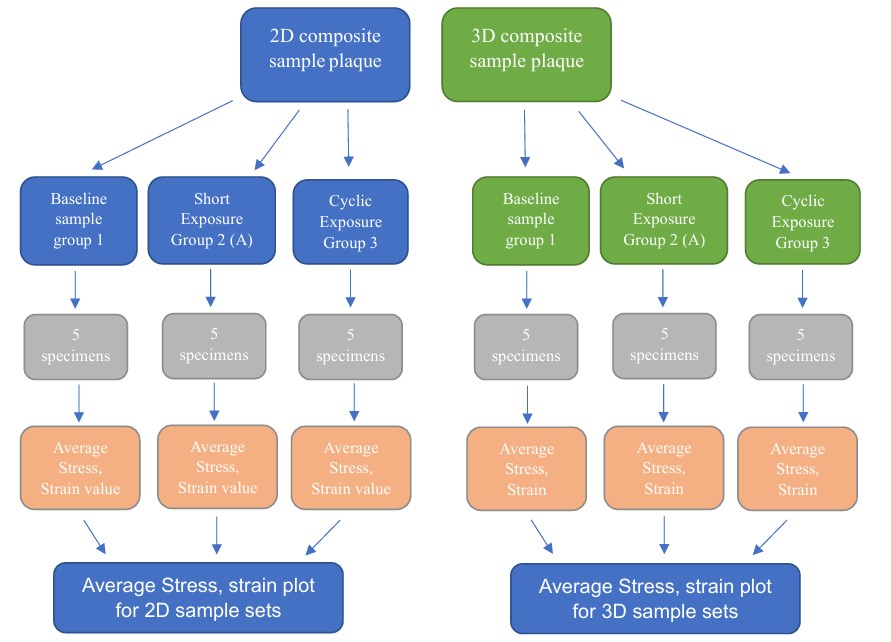

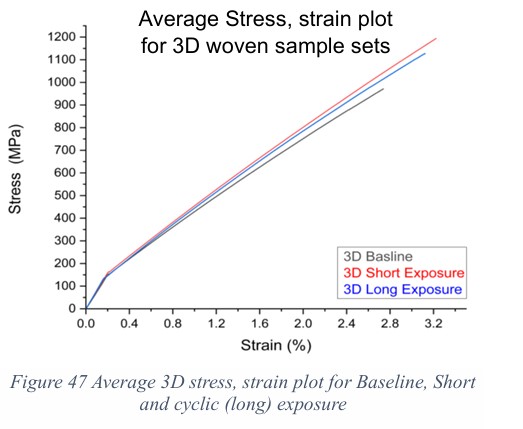

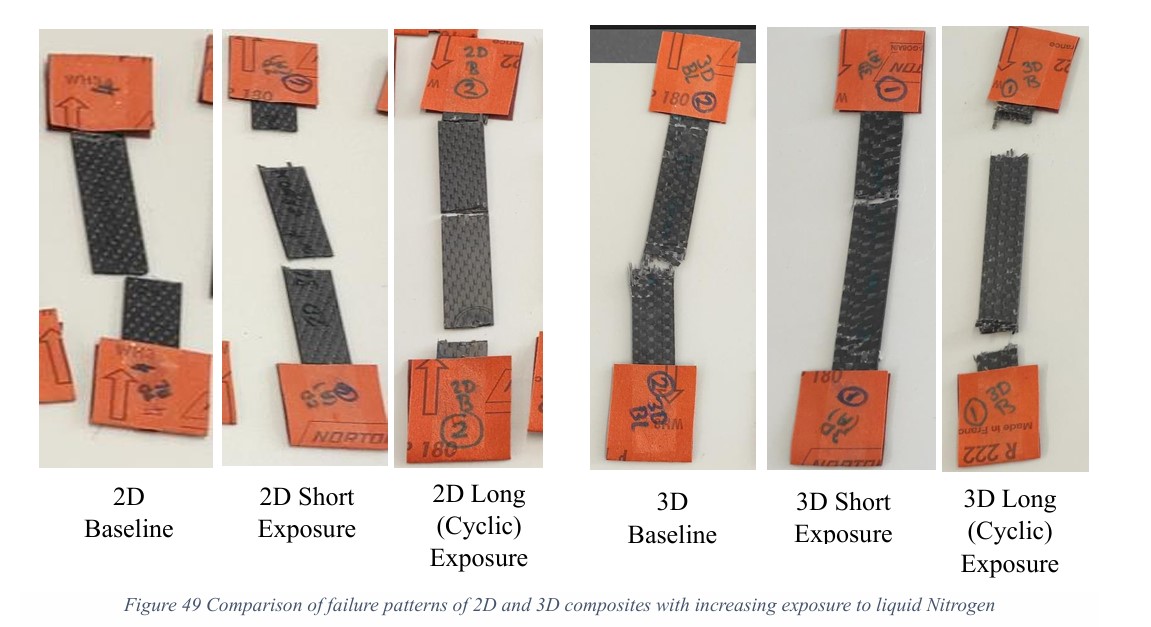

I studied different fibre-reinforced composite architectures, testing how they performed under simulated cryogenic conditions. This involved:

These findings suggest composites could be viable materials for hydrogen storage tanks, but further real-world testing is needed.

My research shows that with the right design, composite materials may help make hydrogen storage safer and more efficient. This could play a small but crucial role in transitioning to cleaner energy systems.